Inserts Specifications . In addition to an overview of cutting tools, safety and precautions, information on calculation. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. A given insert can be specified in either ansi (american) or iso. detailed information on turning inserts identification. these tables show the ansi and iso insert designations for indexable inserts for turning. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory!

from www.slideshare.net

In addition to an overview of cutting tools, safety and precautions, information on calculation. detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. A given insert can be specified in either ansi (american) or iso. the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. these tables show the ansi and iso insert designations for indexable inserts for turning. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the related charts and theory!

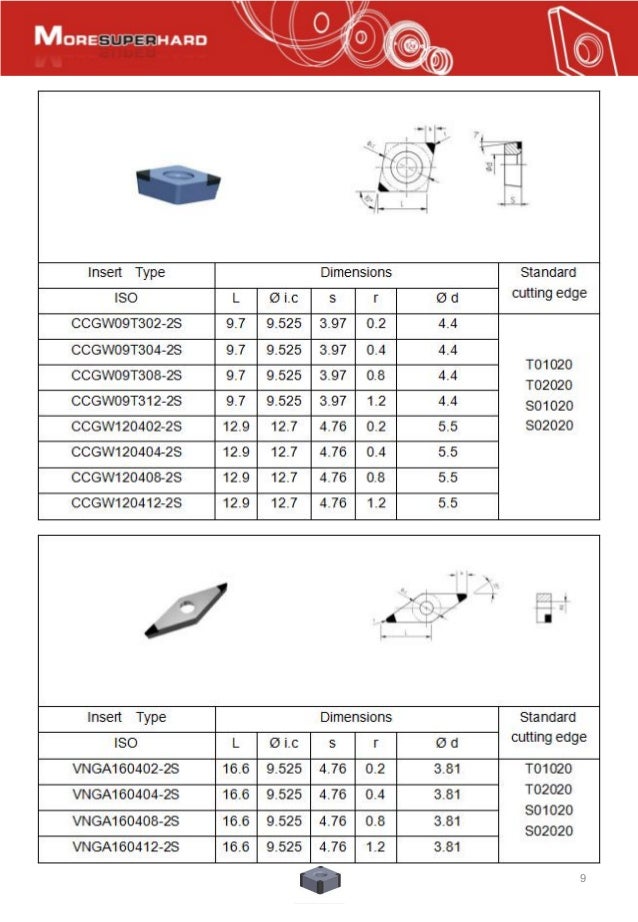

Specification of brazed PCBN inserts, soldering PCBN inserts

Inserts Specifications In addition to an overview of cutting tools, safety and precautions, information on calculation. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. A given insert can be specified in either ansi (american) or iso. In addition to an overview of cutting tools, safety and precautions, information on calculation. Plus, all the related charts and theory! these tables show the ansi and iso insert designations for indexable inserts for turning. detailed information on turning inserts identification.

From www.slideshare.net

Specification of brazed PCBN inserts, soldering PCBN inserts Inserts Specifications Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. these tables show the ansi and iso insert designations for indexable inserts for turning. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. In. Inserts Specifications.

From www.daytontoolltd.ca

CCMTCCGT Dayton Tool Ltd Inserts Specifications A given insert can be specified in either ansi (american) or iso. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. these tables show the ansi and iso insert designations for indexable inserts for turning. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length,. Inserts Specifications.

From www.hfsindustrial.com

Keensert Solid Inserts Inserts Specifications these tables show the ansi and iso insert designations for indexable inserts for turning. detailed information on turning inserts identification. A given insert can be specified in either ansi (american) or iso. Plus, all the related charts and theory! selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius,. Inserts Specifications.

From www.shop-apt.co.uk

SNMG 120408 GM UM25A Carbide Inserts for Turning PVD Coated for Steel, Stainless & General Use Inserts Specifications detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. A given insert can be specified in either ansi (american) or iso. the iso designation system for. Inserts Specifications.

From www.alibaba.com

Stacme29 Degree American Stub Acme Thread Inserts Carbide Inserts For Cutting Buy Carbide Inserts Specifications Plus, all the related charts and theory! Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. A given insert can be specified in either ansi (american) or iso. In addition to an overview of cutting tools, safety and precautions, information on calculation. the iso designation system for indexable inserts (iso 1832) is. Inserts Specifications.

From www.stanleyengineeredfastening.com

Key Locking Threaded Inserts STANLEY® Engineered Fastening Inserts Specifications Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. these tables show the ansi and iso insert designations for indexable inserts for turning. Plus, all the related charts and theory! A given insert can be specified in either ansi (american) or iso. Understanding the material properties and. Inserts Specifications.

From rdbarrett.co.uk

CNMG 190612 Carbide Turning Inserts BY EdgeTech R.D. Barrett Inserts Specifications A given insert can be specified in either ansi (american) or iso. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. In addition to an overview of cutting tools, safety and precautions, information on calculation. these tables show the ansi and iso insert designations for indexable inserts for turning. selecting the. Inserts Specifications.

From www.anzor.co.nz

M10(1.03.5) SS FLANGE HEX THREADED INSERT Anzor Fasteners Inserts Specifications A given insert can be specified in either ansi (american) or iso. In addition to an overview of cutting tools, safety and precautions, information on calculation. these tables show the ansi and iso insert designations for indexable inserts for turning. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the. Inserts Specifications.

From www.katoadvanex.com

Standard Specifications for Tanged Wire Thread Inserts KATO Advanex Inserts Specifications these tables show the ansi and iso insert designations for indexable inserts for turning. Plus, all the related charts and theory! selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Regardless of component size, material or design, the carbide insert grade you use can make. Inserts Specifications.

From www.alibaba.com

Coating Turning Carbide Insert Cutter Pvd Knux160405r Knux160405l Knux160405 Knux 160405 Inserts Specifications Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Plus, all the related. Inserts Specifications.

From www.alibaba.com

16ir 16er Iso Threading Inserts For Stainless Steel Turning Buy Thread Inserts For Ss,Iso Inserts Specifications In addition to an overview of cutting tools, safety and precautions, information on calculation. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! the iso designation system for indexable inserts (iso 1832) is a standardized system to name. Inserts Specifications.

From mungfali.com

Helicoil,helicoil Insert,helicoil Inserts,helicoil,helicoil Kit 109 Inserts Specifications Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. detailed information on turning inserts identification. A given insert can be specified in either ansi (american) or iso. Plus, all the related charts and theory! Understanding the material properties and machining conditions is crucial for optimizing performance and. Inserts Specifications.

From www.kennametal.com

Selecting Carbide Inserts for Metalworking Kennametal Inserts Specifications detailed information on turning inserts identification. Plus, all the related charts and theory! these tables show the ansi and iso insert designations for indexable inserts for turning. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Regardless of component size, material or design, the carbide insert grade you use can make. Inserts Specifications.

From www.slideshare.net

Specification of brazed PCBN inserts, soldering PCBN inserts Inserts Specifications A given insert can be specified in either ansi (american) or iso. detailed information on turning inserts identification. these tables show the ansi and iso insert designations for indexable inserts for turning. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. In addition to an overview. Inserts Specifications.

From eauclairehearth.com

430 Deluxe Gas Fireplace Insert Eau Claire Hearth Inserts Specifications detailed information on turning inserts identification. Plus, all the related charts and theory! Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. In addition to an overview of cutting tools, safety. Inserts Specifications.

From www.alibaba.com

Tungsten Carbide Inserts Cnmg/cnmg120408 Cnc Turning Inserts Buy Cnmg Inserts,Cnmg1204 Inserts Inserts Specifications the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. A given insert can be specified in either ansi (american) or iso. Plus, all the related charts and theory! these tables show the ansi and iso insert designations for indexable inserts for turning. detailed information on turning inserts identification.. Inserts Specifications.

From www.slideshare.net

Specification of brazed PCBN inserts, soldering PCBN inserts Inserts Specifications the iso designation system for indexable inserts (iso 1832) is a standardized system to name an indexable insert. detailed information on turning inserts identification. selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. In addition to an overview of cutting tools, safety and precautions,. Inserts Specifications.

From www.cummingsprinting.com

Insert Specifications Saddle Bound BindIn Cummings Printing Inserts Specifications detailed information on turning inserts identification. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. A given insert can be specified in either ansi (american) or iso. these tables show. Inserts Specifications.